What Is Tire Cord Fabric? The Hidden Backbone of Tire Strength

Views: 0 Author: Site Editor Publish Time: 2025-06-23 Origin: Site

Did you know? Cord fabric isn’t just for decoration—it holds up the entire weight of your car. A single tire contains about 400g of cord yarn, yet it supports a 1.5-ton vehicle at highway speed. So how does something so light carry so much? This hidden backbone is called tire cord fabric—and it does more than you might think. In this post, you’ll learn what tire cord fabric is, how it works, and why it matters. We’ll explore its structure, materials, performance, and future in EVs and sustainable mobility.

1. What Is Tire Cord Fabric and Why Does It Matter?

Tire cord fabric may look simple, but it is actually a marvel of engineering. It’s made from high-performance yarns, woven into a fabric that reinforces and stabilizes the rubber structure of the tire. These fibers are designed to hold shape, resist heat and pressure, and maintain integrity even under extreme conditions. Each component of the fabric plays a role. Some materials provide flexibility for comfort and ride quality. Others offer tensile strength to resist deformation or withstand load-bearing stress. Combined, they create a strong, reliable support layer inside every tire.

Core Features of Tire Cord Fabric

Different properties work together in tire cord fabric to ensure safety and durability on the road. Key features include:

Tensile Strength: Withstands vehicle weight without collapsing

Shock Absorption: Reduces damage from road impacts

Anti-Deformation: Keeps tire shape stable under stress

Thermal Resistance: Endures heat from friction and high speeds

Shape Control: Maintains form and enhances ride comfort

These strengths allow the tire to function reliably, mile after mile, even under intense conditions.

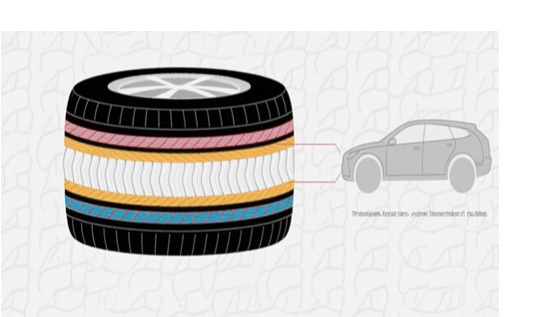

Where It Sits in a Tire

Tire cord fabric is embedded in multiple internal layers. Each placement has a specific function.

| Tire Layer | Cord Fabric’s Role |

|---|---|

| Carcass (body ply) | The main backbone that carries internal pressure |

| Belt Layer | Helps reduce tread deformation at high speed |

| Cap Ply (optional) | Improves stability, especially in high-performance tires |

Though hidden from view, these layers form the backbone of every safe, high-performing tire.

2. Materials and Structure: From Yarn to Backbone

Tire cord fabric may look like a simple mesh—but it’s built from highly engineered materials. These fibers are carefully chosen for their ability to withstand pressure, temperature, and fatigue. Each material contributes unique traits. Some enhance flexibility to smooth out road impact. Others provide unyielding strength to hold shape and bear weight. Here are the most common types used in the industry today.

Types of Cord Fabric Materials

| Material | Key Traits | Common Use |

|---|---|---|

| Polyester (HMLS) | High modulus, low shrinkage, holds shape well | Most passenger car tires |

| Nylon 6/66 | Impact-resistant, good heat fatigue resistance | Heavy-duty and off-road tires |

| Aramid (Kevlar) | Very high strength, lightweight | Racing, high-speed, performance |

| Rayon | Smooth finish, decent flexibility | Niche use, less common today |

| Steel Wire | Extremely strong, no stretch | Truck, aircraft, commercial tires |

Each yarn goes through precision processing to become part of a high-strength tire structure.

How the Structure Comes Together

The process begins with yarn twisting. Twisting improves strength and balance. The twisted yarns then undergo a dipping process—usually an RFL (Resorcinol-Formaldehyde-Latex) coating—to ensure strong adhesion to rubber.

The warp yarns, running lengthwise, provide core support. Weft yarns run across and hold the structure together. Once coated, the fabric is bonded to the rubber under high heat—around 200°C—forming a unified, durable carcass.

This bonding process transforms fiber into structure. The final fabric layer performs reliably under stress, heat, and heavy use.

3. Strength and Safety: What Tire Cord Fabric Really Does

Tire cord fabric is more than a support layer—it actively protects your tires every time they roll. This high-strength textile keeps the tire stable, intact, and safe under extreme road and load conditions.

a. Elastic and Tear-Resistant

Polyester HMLS yarn is widely used because of its unique balance: it stretches under pressure but doesn’t break. This allows the tire to flex when hitting bumps or curbs without tearing the inner structure. For example, when a tire hits a pothole, the sudden force pushes the rubber inward. The elastic cords expand slightly, then return to shape—like shock absorbers inside the tire walls. This elasticity keeps the carcass intact and prevents cracks from forming in the rubber layers.

b. Heat-Stable and Fatigue-Resistant

Tires generate significant heat—especially during long drives or at high speeds. Cord fabrics like aramid and polyester HMLS retain strength at temperatures approaching 200°C. Even under prolonged stress, they don’t degrade or deform. This resilience prevents layer separation or tread distortion, keeping the tire safe and in shape.

c. Shape Control and Ride Comfort

Cord stiffness directly influences driving comfort and precision. Stiff cords improve road grip and handling response. Softer cords reduce vibration and absorb minor bumps. By tuning the cord’s properties, tire makers can match performance to vehicle type—sporty, luxury, off-road, or standard daily driving.

d. Load-Bearing Power

Tire cord fabric may weigh less than a can of soda, yet it can support 1.5 tons of pressure. This strength comes from layered cords that spread vehicle weight evenly. Each layer acts like a beam in a bridge—together they prevent sidewall ballooning, keep tire shape intact, and protect against blowouts.

| Protection Function | How It Works | Result |

|---|---|---|

| Elasticity under pressure | Expands and returns to shape when hit or flexed | Prevents cracking, protects inner layers |

| Thermal resistance | Withstands heat buildup during high-speed or long-distance driving | Keeps shape, stops structural fatigue |

| Controlled stiffness | Tailors ride comfort and handling through cord rigidity | Reduces wear, improves driving experience |

| Load distribution | Spreads pressure across multiple cord layers | Prevents blowouts, supports heavy loads |

4. Real-World Use: How Cord Fabric Fits Different Tires

Cord fabric isn’t one-size-fits-all. Different tires demand unique strength, stiffness, and heat resistance. The right fabric keeps your wheel safe and reliable, no matter the application.

a. Tailored Tire Applications & Fabric Choices

When it comes to passenger cars, polyester and aramid are the go-to materials. Polyester holds its shape well and keeps costs low, making it a popular choice for about 45% of the market. For sportier models, aramid cords trim weight and sharpen handling, providing a better driving experience. Electric vehicles (EVs) present unique challenges. EV tires degrade about 30% faster than those on internal combustion engine (ICE) vehicles. To combat this, aramid reinforces high-heat zones, while lightweight polyester adds low rolling resistance, extending the vehicle’s range by up to 6%.

Trucks and commercial vehicles require durability and load capacity. Nylon 6 cording handles impact and resists fatigue, making it ideal for these applications. Steel wire belts boost load capacity in the sidewalls, enhancing durability and preventing blowouts. For aircraft and off-road vehicles, the conditions are extreme. Operating pressures exceed 200 psi, and impacts are rugged. Only aramid and high-modulus steel cords can resist tearing and hold their structural shape under such forces.

b. Concrete Examples & Data Insights

In the case of passenger SUVs, polyester cords are commonly used. These fabrics are dimensionally stable and dominate the market, making up about 45% of market share in radial tires. Their balance of performance and price makes them a practical choice for everyday driving. Electric cars face a unique challenge: their tires wear about 30% faster than those on ICE vehicles. To address this, aramid-reinforced designs withstand the frequent heat spikes from regenerative braking, while lightweight polyester keeps rolling resistance low. This combination can extend the vehicle’s range by up to 6%.

Heavy trucks rely on Nylon 6/66 cords for their fatigue resistance and strong rubber bonding. Steel-wire belts provide extra weight support, enhancing sidewall durability and preventing blowouts. These materials are essential for vehicles that carry heavy loads over long distances. Aircraft and off-road vehicles operate under extreme conditions. With operating pressures exceeding 200 psi and frequent rugged impacts, only aramid and high-modulus steel cords can provide the necessary strength and durability. These materials resist tearing and maintain structural integrity, ensuring safety and reliability.

5. Challenges and What’s Next for Cord Fabric Technology

Cord fabric has come a long way, but it's not done evolving. As the auto industry shifts toward cleaner, smarter, and faster vehicles, the demands on this hidden layer grow stronger. Let’s look at what challenges lie ahead and where the future is headed.

a. Greener, Cleaner Materials

Sustainability is no longer optional. Carmakers and tire manufacturers now seek eco-friendly solutions from the inside out. New research focuses on using recycled fibers, such as PET from bottles or reclaimed nylon waste, to reduce the reliance on petroleum and lower CO₂ output. They are also exploring low-VOC adhesives to reduce toxic emissions during the coating and bonding processes, as well as biodegradable coatings that allow parts to break down more cleanly at the end of their life. The goal is to create durable fabric that’s kind to both tires and the planet.

b. Materials for EV-Only Tires

EV tires bring new stress—instant torque, added battery weight, and fast wear. Traditional cords don’t always hold up. Innovators are now testing ultra-light cords to reduce rolling resistance, high-heat-resistant aramid blends for regenerative braking cycles, and hybrid weaves that combine stiffness and flexibility. These changes help EVs stay quiet, efficient, and long-lasting—even under pressure. The focus is not just on speed but on surviving high loads and harsh cycles, day after day.

c. Smart Fabric for Safer Tires

Tomorrow’s tires won’t just roll—they’ll think. Researchers are embedding sensors directly into tire cord layers. These sensors can detect micro-cracks before they become dangerous, monitor tension and temperature changes in real time, and alert drivers or fleet systems when wear becomes unsafe. Imagine a tire that tells you it’s time to rotate—or warns you before a blowout. That’s where smart cord fabric is heading. The future of tire cord fabric includes strain sensing to track load and deformation, temperature alerts to flag overheating in tread zones, and predictive analytics to help schedule tire service earlier.

6. Frequently Asked Questions (FAQ)

What exactly is tire cord fabric?

Tire cord fabric is a high-strength textile layer inside tires—made from twisted, coated yarns (like polyester, nylon, or aramid)—that reinforces and holds the tire’s shape under pressure and heat.

Why is tire cord fabric vital for EV tires?

Electric vehicles place extra stress on tires due to higher torque and braking heat. Specialized cords, such as lightweight polyester and aramid blends, reduce rolling resistance and boost heat resistance to extend tire life.

Can recycled or greener materials replace standard cords?

Yes. Manufacturers are testing recycled PET yarns, low-VOC adhesives, and even biodegradable coatings. These alternatives aim to reduce environmental impact while maintaining performance and durability.

How much fabric is in a typical tire?

Each tire contains roughly 400 grams of cord fabric. Despite its light weight, this material supports up to 1.5 tons by distributing force across multiple internal layers.

What materials are used for commercial truck tires?

Truck and bus tires often combine nylon cords for shock absorption with steel wire belts for load-bearing strength. This combo helps manage heavy cargo and rough conditions without blowouts.

What are the latest innovations in cord fabric tech?

Smart cord fabrics are being developed with embedded sensors that track heat, pressure, and strain. These can warn drivers about internal tire damage before failure occurs, supporting predictive maintenance and safety.

7. A Hidden Hero Beneath Every Tire

Tire cord fabric is the backbone of tire safety and strength. Though invisible, it supports shape, load, and control on every drive. As vehicles shift toward green and smart mobility, cord tech races ahead. Its role is quiet—but essential—for every road ahead.

QUICK LINKS

CALL US

Phone: +86-13285110895